Detailed Woodworking Plan for a Family-Sized Four-Seater Picnic Table

I. Introduction

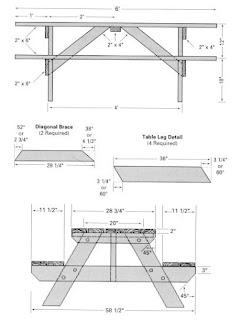

This document provides a comprehensive woodworking plan for constructing a durable and aesthetically pleasing four-seater picnic table suitable for family use. The design emphasizes straightforward joinery techniques achievable by intermediate-level woodworkers, prioritizing strength and longevity. Detailed dimensions and material lists are provided, alongside step-by-step instructions and illustrations (not included in this text-based plan, but readily imagined or drawn separately). The chosen material is pressure-treated lumber, ensuring weather resistance and minimizing maintenance. This plan prioritizes safety and stability, incorporating robust construction methods to withstand regular use and the elements.

II. Materials List

The following materials are required for this project. Adjust quantities as necessary based on lumber dimensions and potential waste.

A. Lumber:

- Four 4x4 pressure-treated posts: 30 inches long (legs).

- Two 2x6 pressure-treated boards: 72 inches long (top supports - lengthwise).

- Four 2x6 pressure-treated boards: 60 inches long (seat supports - across the length).

- Two 2x12 pressure-treated boards: 72 inches long (table top).

- Four 2x12 pressure-treated boards: 60 inches long (table seats).

- Various scraps of 2x4 pressure-treated lumber: for bracing and reinforcement (quantities to be determined during construction).

B. Hardware:

- 36 Exterior-grade wood screws: 3 1/2 inches long.

- 24 Exterior-grade wood screws: 2 1/2 inches long.

- 8 Exterior-grade carriage bolts: 5/16 inch diameter x 4 inches long (for leg-to-support connection).

- 8 Washers: to fit carriage bolts.

- 8 Nuts: to fit carriage bolts.

- Wood glue (exterior grade): For added strength and water resistance in joints.

C. Tools:

- Measuring tape and pencil

- Circular saw or miter saw

- Drill with various drill bits (including a 5/16 inch drill bit for carriage bolts).

- Screwdriver (impact driver recommended)

- Wrench (to tighten carriage bolts)

- Safety glasses

- Work gloves

- Clamps (various sizes)

- Level

- Sandpaper (various grits)

- Wood sealer/stain (optional)

III. Construction Steps

The following steps outline the construction process. Accuracy and precision are crucial at each stage to ensure the final product's structural integrity and aesthetic appeal.

A. Preparing the Legs and Supports:

- Cut the four 4x4 posts to 30 inches in length. Ensure all cuts are square and accurate using a miter saw or circular saw and a speed square.

- Cut the two 2x6 top supports to 72 inches. These will run the length of the table, forming the frame connecting the legs.

- Cut the four 2x6 seat supports to 60 inches. These will span the width of the table, connecting the legs and forming the base for the seats.

- Lightly sand all cut edges to remove any splinters or rough surfaces.

B. Assembling the Table Base:

- Pre-drill pilot holes at each leg's end to prevent wood splitting when driving in screws. This is especially important with pressure-treated lumber.

- Attach the top support beams to the legs using the 3 1/2-inch exterior-grade wood screws. Ensure that the supports are flush against the legs and parallel to each other.

- Attach the seat support beams to the legs using the 3 1/2-inch exterior-grade wood screws. Ensure that the seat supports are equally spaced and perpendicular to the top supports.

- Reinforce the leg-to-support connections using the carriage bolts. Pre-drill holes for the bolts to prevent splitting. Insert the bolts through the legs and supports, add the washer and nut, and tighten securely.

- Check the levelness of the table base; adjust as needed using shims if any legs are uneven.

C. Attaching the Tabletop and Seats:

- Cut the two 2x12 boards for the tabletop to 72 inches. Sand all edges thoroughly.

- Cut the four 2x12 boards for the seats to 60 inches. Sand all edges thoroughly.

- Apply a generous amount of exterior-grade wood glue to the top supports and position the tabletop boards onto the supports.

- Secure the tabletop boards to the supports using the 2 1/2-inch exterior-grade wood screws. Space the screws evenly along the length of each board.

- Apply a generous amount of exterior-grade wood glue to the seat supports and position the seat boards onto the supports.

- Secure the seat boards to the supports using the 2 1/2-inch exterior-grade wood screws, evenly spacing them.

D. Finishing Touches:

- Carefully sand all surfaces of the completed picnic table to smooth out any rough edges or imperfections. Start with a coarser grit sandpaper and gradually move to a finer grit for a smoother finish.

- Apply a wood sealer or stain (optional) to protect the wood from the elements and enhance its appearance. Follow the manufacturer's instructions for application and drying time. Allow ample drying time before use.

- Inspect the entire structure for any loose screws, wobbly legs, or other issues. Tighten any loose screws or make necessary adjustments as needed.

IV. Safety Precautions

Safety is paramount throughout this project. Always wear safety glasses and work gloves. Use caution when operating power tools, following all manufacturer's instructions. Ensure proper ventilation when working with wood stains or sealers. Dispose of sawdust and waste materials responsibly.

V. Conclusion

This detailed plan provides a comprehensive guide for building a sturdy and attractive four-seater picnic table. By following these instructions carefully and utilizing the recommended materials and tools, you can create a lasting piece of outdoor furniture for your family to enjoy for years to come. Remember that accuracy and attention to detail are crucial for a successful outcome. Always prioritize safety and take necessary precautions throughout the construction process.

0 comments:

Post a Comment

Note: Only a member of this blog may post a comment.